More lift talk

Hello all. This is my first post here. I have been reading on this, and other forums for about a month now. I have decided to join this group as you all seem to have your shit together. and there is a good mix-up of people, bringing good ideas.

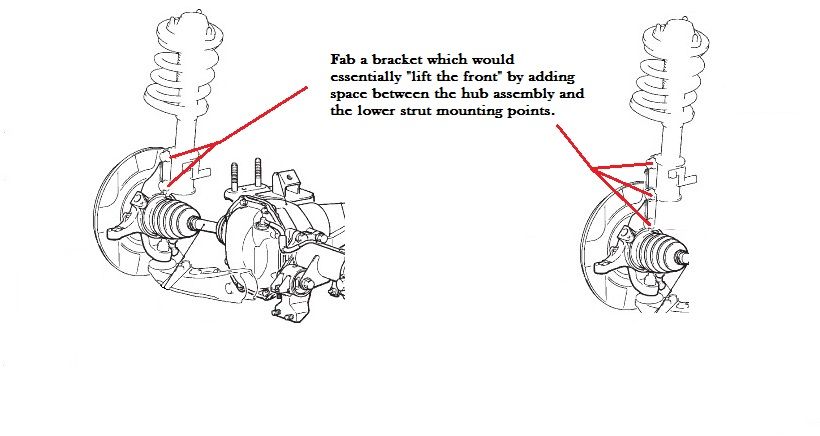

After reading quite a few posts about lifting the pajaro, i have seen all kinds of ideas. some which make sense to me and some that don't. however i have yet to see someone add lift by "spacing" out the bottom. I've been turning the idea over in my head, and feel its doable. See picture below for a rough visual of what i'm trying to do.

By doing this i would give myself about 100mm of lift up front (this is an eyeball measurement) i would need to lower the diff by about 17mm. this would also free up generous space for wider and taller tires. This is due to the fact that the lower spring plate has been effectivly move up by 100mm.

now with that being said i have going on assumption that for lift in excess of 30mm it is ideal to drop the diff 10mm (ex. 60mm lift = 10mm diff drop). Is this correct? Also the tolerance for for total lift is 100mm with out the need for exhausting custom work. Is this correct?

Is there a reason no one has done a lift in this way? Thank you all for any feedback. it is much appreciated.

Thank you Claude

Thank you for clearing up the whole lift:diff drop bit for me. i always have a tendancy to over think simple stuff like that.

As far as "droop" (we call it negative travel) a solution is simple; limiting strap. A limiting strap solves the issue of over extension. they are commonly used in baja rigs and crawler rigs to prevent over flexing of the suspension; inturn causing damage to cv joints, tie rods, axel joints etc... for my purpose i plan to first lift the front end up, completely unloading the suspension in stock form. measure the distance from the lower bolt on the lower strut to any point on the inner fender-well (at this point a bracket will be welded in) the strap will be placed between the two points. the key is to allow a full range of positive travel (compression) but limit negative travel (unloading) to factory specs. the limiting strap is far cheaper than buying or fabricating longer suspension bits, and much less of a headache than doing the math to get propper length bits.

here is a link:

http://www.offroad-engineering.com/limiting-straps-quad-straps.html

and a photo:

strap

I understand, and it will probably work on some car. I think (again, not an engineer comment!) that the problem with the io is not that the droop is too much, it is the wrong way around,

If you replace the front spring by a higher one to lift the car, you won't have any droop left (around 2 inch, one inch should be ok). Not having any droop can be dangerous, but the strap are not needed here....this is if I understood, properly, your idea...:)

Happy io

I'm with Claude here - I think you're looking at trouble...

First - I'm pretty certain I've seen this idea before, possibly in this forum.

Second - based on the discussions in this forum - the maximum safe lift without a diff drop would seem to be 50mm, a 100mm lift will therefore place your CVs at risk with the vehicle at "rest height", unless you go with a diff drop of at least 50mm, in which case the CVs are at risk as soon as any droop occurs - ideally you need a diff drop matching the lift.

Yes, you could use a strap to limit droop and protect the CVs that way, but what you're really doing is limiting articulation - take a look at Claude's avatar - having the wheel on the ground gets power to the ground.

Next - as I understand it a diff drop on an iO actually lowers the cross member and with it the entire power plant - but - a diff drop of 100mm without dropping the transmission crossmember by a similar amount will result in extreme changes in the drive shaft angles as the transmission & transfer case will now be nose down, tail up and at a time where you presumably have a matching 100mm lift at the rear so the rear axle is 100 mm lower down

Yep...

This isn't making a whole lot of sense to me either I'm afraid. I believe it was Fielies who tried the lower mount spacer and found he couldn't get the clearance needed for the wheel. Apart from the engine driveshaft angle you also can't drop the engine/diff much more than 25mm without major surgery on the cross member.

strut

If that bracket is made by an engineer...but because they are other way...

What may be done to extend the strut, but not on the lower section is by cutting the tube and extend it, and then fitting a new insert (koni) with a spacer at the bottom of the new longer tube (strut, under the insert) equal to the extension. This way you get the lower plate of the spring higher, can fit you bigger tyres that you want, got a new insert, and a good professional welder can keep the strength of the strut without to much problem (probably a lot less that making this bracket)

Still have to do a diff drop, and modified other bits if you go for a big lift ( brake line...not sure about the rest...)

I think that I have seen something similar on another io, I will put a picture if I find it.....

Talk about luck, found it straight away! you can see the welding on the yellow strut....same result...lot easier to do (to me anyway!!) the bolt at the bottom is to hold the insert.

Happy io

Sorry been away for a bit due

Sorry been away for a bit due to work, this is pretty common.

after reading and looking at my suspension bits, i will agree, 4 inches of lift is far too much unless i plan to do modifacations to drive shafts (all three) and control arms. while this maybe something i may look into after a while. first i will need to to engine work. the little motor frankly doesn't have enough hp/tq to support more rotating weight in the drive shafts and tires. that being said i may be able to do something simple, but still in line with what i had planned. i just have to figure out if camber adjustment will support it. i plan to move the shock a bit further inboard and slightly higher.

should be no more than 10mm inboard and 30mm up. first i will fab it up out of a block of wood, check how the supension and steering act when moved through out their respective range of motions. if it works then i'll fab it up from steel, or have a buddy machine it from aluminum. if its stupid then i can adjust fire as need, and it only coast me a block of wood.

I don't see it happening ...

Go ahead, get out your block of wood - but here's where I see the stumbling block ![]() .

.

The top of the knuckle where the strut ears bolt up is a solid chunk of cast iron, perhaps 20~25mm thick, the strut ears are exactly the same distance apart - your adapter/spacer has to be "stepped" - inner end narrow enough to fit between the strut ears, outer end wide enough to fit over the knuckle - I can't see you doing it with less than a 30~40mm spacing (so it's clear you're going to be moving the bottom of the strut in 15~20mm, and the top of the knuckle out by the same distance.

The strength of the material used to fabricate the adapter is going to be a critical factor, and the suspension geometry changes are going to be significant - you will probably end up with significant positive camber.

The alternative is to narrow the top of the knuckle (and risk reducing it's strength or to use a different strut with the ears further apart (or cut and reweld the ears on these struts - which is not advisable) - extending the lower part of the strut and fitting an insert, like in Claude's picture would probably be easier & safer

Good in put

I hope to not incure too much camber change. i haven't taken measurements to run the math to see exactly what the change will be. im worried most about full lock. camber seems to gain a lot in the positive department depending on the side (right wheel if locked left, and vice versa)

Camber change on full lock is unavoidable.

I don't think I've ever seen a vehicle where there was no a change, and sometimes significant change in camber on full lock - I wouldn't worry too much about it, how much of your time do you plan on spending at full lock?

Having asked that, I will admit that I suspect the majority of my tire wear occurs at or close to full lock in my own driveway - parking the vehicles involves a "parallel parking style manouver" combined with a tight right angled turn - the drive way is double width, but the entrance is single width - it's not too bad with the FWD cars, but the two RWD ones (the Grand Vitara & the Pajero iO) scrub the front tires badly.

this idea is a flop

Go ahead, get out your block of wood - but here's where I see the stumbling block ![]() .

.

The top of the knuckle where the strut ears bolt up is a solid chunk of cast iron, perhaps 20~25mm thick, the strut ears are exactly the same distance apart - your adapter/spacer has to be "stepped" - inner end narrow enough to fit between the strut ears, outer end wide enough to fit over the knuckle - I can't see you doing it with less than a 30~40mm spacing (so it's clear you're going to be moving the bottom of the strut in 15~20mm, and the top of the knuckle out by the same distance.

The strength of the material used to fabricate the adapter is going to be a critical factor, and the suspension geometry changes are going to be significant - you will probably end up with significant positive camber.

The alternative is to narrow the top of the knuckle (and risk reducing it's strength or to use a different strut with the ears further apart (or cut and reweld the ears on these struts - which is not advisable) - extending the lower part of the strut and fitting an insert, like in Claude's picture would probably be easier & safer

you were right... i trashed the idea after putting the truck up on lift and started taking measurments. I just wanted to update this thread, in case there is anyone else looking at something similar. sure you could do it this way, but the amount of fabrication does not justify the results.

suspension lift

Ok, regarding the lift from the lower section of the strut. Your idea a as you said is doable but it does required a modification that is not easy to do and need to be as strong as the original one. Instead of adding extra height at the lower section of the strut, some, choose to add a spacer at the top of the strut, a lot easier to do.

The problem with the spacer, compare to your idea is that the lower plate of the strut is not going up to free some place to bigger tyres. I think that, most people that want to fit much bigger tyres modify the strut by a coil over, this is using smaller (in diameter) spring and does leave room for the big tyres. I haven't seen anyone modifying the lower section of the strut, this doesn't mean that it haven't been done or that it is a bad choice....

For the height that you want to lift your car, a member have posted some very good measurement check here http://pajerio.com/forum/max-lift-disagreement-camber-correction-droop I think that the relationship suspension lift to diff drop should be that the suspension lift shouldn't be more than 45 mm, over 45 mm you should drop the diff by the difference, example.....suspension lift of 100 mm, you got your safe 45 mm and 55 mm over, so you should drop the diff by 55 mm.

Going over 45 mm suspension lift, will bring the angle of the CV joint to the maximum angle, over and you are taking some risk.

All this is what I have learn from this site, and it is not a rule as such, more experience from other and my understanding of it....as I keep saying....I could be wrong...ask my wife !! I am sure that other member will add some more info....

I hope this helps and, again, welcome....

Happy io

My io is now SOLD Thankshttp://pajerio.com/forum/claudes-io-2002-zr-built-thread-onlyhappy-io